|

Lipochem has taken yet another step towards becoming a pioneer provider of the Biodiesel Technology features with feedstock flexibility which enables your biodiesel plant to be robust enough to efficiently and consistently process feedstock with high FFA, moisture and impurities.

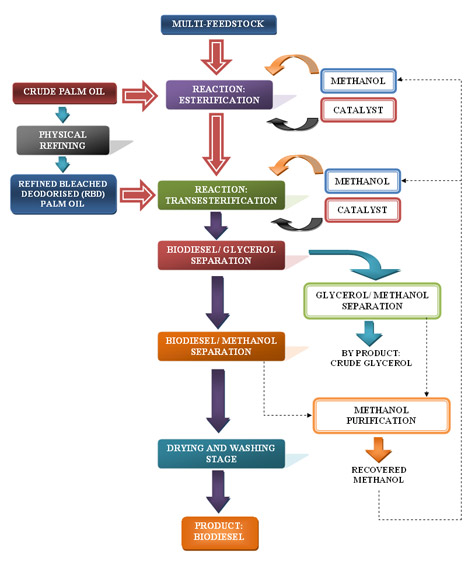

Multi-Feed Stock Biodiesel Process Flow

Click the image to enlarge!!!

Lipochem’s Multi-feedstock Biodiesel Plant, a historical breakthrough in biodiesel industry, allows your plant to process high valuable biodiesel with cheaper raw material such as PFAD, CPO, etc. The biodiesel produced meets or exceeds international standard EN 14214 and is exported to

many countries including the European countries.

With improved process design, Lipochem’s Multi-Feedstock Biodiesel Plant enables production with high yield

at low operating cost, by minimizing the consumables, such as resins, co-solvent, catalyst, etc. With low capital investment, operational costs and cheaper feedstock, this plant guarantees a high return on investment especially with the overwhelming demand for Biodiesel in the global market.

Lipochem Multi-feedstock Biodiesel Plant’s results

| |

Results |

EN Specification |

| AV, mgKOH/g |

<0.4 |

0.5 (Max) |

| Moisture, ppm |

<400 |

500 (Max) |

| Ester Content, % |

>96.5 |

96.5 (Min) |

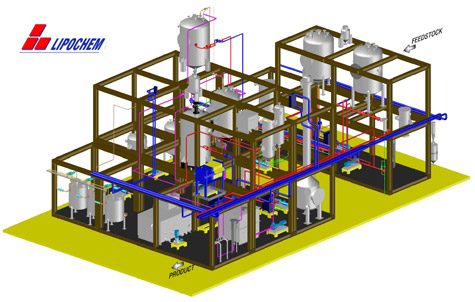

Lipochem delivers biodiesel plant capacities from 60,000 up to 250,000 metric tons per year.

Click the image to enlarge!!!

|